Published on Aug 21, 2023

Wastewater is defined as the flow of used water from homes, businesses, industries, commercial activities and institutions which are subjected to the treatment plants by a carefully designed and engineered network of pipes. This type of wastewater is classified and defined according to its sources of origin. Typically 200 to 500 litres of wastewater are generated for each person connected to the system every day.

The amount of flow handled by a treatment plant varies with the time of day and with the months of the year. The processes reviewed here include both those that remove pollutant dirts in wastewater and those that vanishes them. Using a wastewater treatment technology that removes, rather than destroys, a pollutant will give a treatment remains.

At wastewater treatment plant, this flow is treated before it is allowed to be returned to the environment. There are no holidays for wastewater treatment, and most plants operate 24 hours every day of the week. Wastewater treatment plants works on critical point of the water cycle, helping nature protects water from the excessive pollution. Most treatment plants have primary treatment and secondary treatment . A short description about the primary treatment which includes screening whereas secondary treatment involves activated sludge, trickling filters etc. and also to measure removal of the carbon in the wastewater treatment processes can be done by TOC(Total organic carbon), BOD(Biochemical oxygen demand), and COD(Chemical oxygen demand) is also explaned here.

The Maharashtra floods refers to the flooding of many parts of the Indian state of Maharashtra including large areas of Mumbai city located on the coast of the Arabian Sea, on the Western coast of India, in which almost 1,094 people died. It occurred one month after the June 2005 Gujarat floods. Large numbers of people were stranded on the road, lost their homes, and many people walked very long distances back home from work that evening. The floods were caused by the heaviest, ever recorded 24-hour rainfall of 944 mm (37.17 inches) which lashed the metropolis on 26 July 2005, and continued for the next day. 644mm (25.35 inches) was received within the 12-hour period between 8am and 8pm.

The rainfall continued for the next week. The highest 24-hour period in India was 1,168 mm (46.0 inches) in Aminidivi in Lakshadweep on 6 May 2004 although some reports suggest that it was a new Indian record. Keeping in mind the natural calamities and Swachh Bharat Abhiyaan we have made this project.As this project is very compact as compared to other municipal machineries used to drain out the wastes.As the big machineries causes traffic jams on the roads and highways,but by using this we can easily remove waste easily and without causing any traffic jams.

Wastewater is defined as the flow of used water from homes, businesses, industries, commercial activities and institutions which are subjected to the treatment plants by a carefully designed and engineered network of pipes. There are large no.of machines used for removing out the wastes from drains.

Every dynamic spring is subject to these constraints where variation of forces and alignment takes place. To find a solution for the problem of water logging due to plastic, thermocol, metal, etc.To treat problems like malaria, typhoid, etc. caused due to water accumulation.

By doing some research in the past we can say that it is seen that major factors that affect the strength of the machine are design parameters, material selection, raw material defect, and surface imperfection. It is seen that design parameters i.e. operating modes, operating temperature, and imperfections, as we seen as temperature increases the strength of material decreases.

The main objective of this project to minimize or overcome the problem which can faced in manual machine. Also increased the dumping rate of waste. And help to operator do easily work. The purpose of selecting drain waste water cleaner machine are is follow- • Simplicity of Design and Control. • This type of machine are easy to operate and less time consuming.

• Evaluate the effectiveness of alternative drainage design and operational practices, to reduce nitrate-N losses from drained agricultural lands

. • Assess the impact of various soil and crop management practices on reducing nitrate-N loadings to subsurface drains.

• Assess the need for further research in other aspects of water quality from drained agricultural lands, including the emerging issues of pathogens and phosphorus from manure applications.

• Develop drainage guides and other extension materials, and work with state and federal action agencies, to assist in implementation of improved design and management practices for subsurface drainage systems

• Low-cost drain-off solution if drains already exist.

• Construction materials are often locally available

• Creates employment (construction and maintenance)

• It is Portable

• It can be used in BMC

• It can be used to separate plastic, thermocol from sewage

• It can be used in plastic industries

5 inch sprocket- 4 nag

30 inch chain- 2 nag

AC supply gear motor

speed of gear motor- 20 RPM

Voltage required – 230 volts

0.5 Horse Power

Torque of gear motor- 40 to 50 kg

Upper and bottom diameter of shaft -25mm

4 ball bearing- ID=19mm

Adjustable plate as per required height

Back side waste bin

Lifting mechanism attached on chain

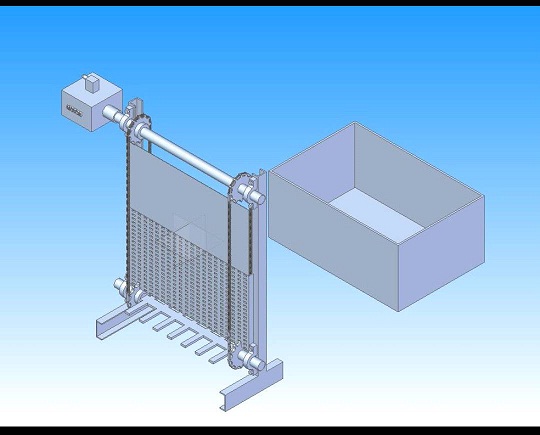

The components used in this Darin Waste Water Cleaner are AC geared motor,upper and lower shaft,ball bearings,backside waste bin,adjustable plates,chain drive.the material used for C.I for frame,for ball bearing the type of bering used is pillw block ball bearing made of C.I,galvanised steel is used for waste bin.

Our project is simply a drain waste water cleaner machine, which is automatically operated .Following different modification can be done to improve the output and efficiency.we have use a geared motor,adjustable plates,backside waste bin,single plate clutch,springs,. This machine can be placed inside the drainage pipe to remove all the wastes like plastic,thermocol,etc. Hence by having above modifications above machine can be made a multipurpose output machine, which can be may power driver and automatically operated.

The drain waste water cleaner machine is designed and manufactured by using gear changing and shaft coupling principle. It consist mainly DC geared motor, shafts, waste removal plates, dust bin, bearings, sprocket and chains.Construction materials are easily available,creates employment( construction and maintainence),simple to construct.

1. INTERNATIONAL JOURNAL OF ENGINEERING RESEARCH AND APPLICATION (IJERA)

2. INTERNATIONAL JOURNAL OF ADVANCE ENGINEERING AND RESEARCH (IJAER)

3. https://en.wikipedia.org/wiki/Drainage_system

4. http://www.mdpi.com/2073-4441/6/4/976