Published on Sep 03, 2023

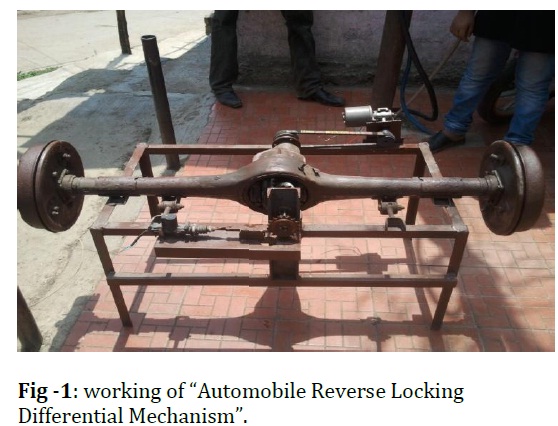

The “Automobile Reverse Locking Differential Mechanism” is a preferred embodiment provides systems and methods for preventing a vehicle from reverse movement on a slope. This system consists of a heavy commercial vehicle, ratchet and pawl device connected to at least one wheel of the vehicle and actuator which will control the movement of the pawl while engaging or disengaging the mechanism where in the system may be engaged using an engaging mechanism when reverse motion is undesirable or to be restricted, and may be disengaged when the reverse motion is desirable.

A differential is a device which is used in vehicles over a few decades and when vehicle is negotiating a turn, the outside wheel travels a greater distance and turns faster than the inside wheel. The Differential is the device transmitting the Power to each wheel, allows one wheel to turn faster than the other. It splits the engine torque two ways, allowing each output to spin at a different speed. The differential is found on all modern cars and trucks, and also in many all-wheel-drive (full-time four-wheel drive) vehicles.

The land transport sector encompasses the commercial use of many different vehicles including Lorries, light vans, taxis, buses, cars construction and agricultural machinery, emergency service vehicles, motorcycles, mopeds and bicycles. Road transport safety is an important issue in the land transport sector. Driving mistakes made by heavy goods vehicle drivers may be more serious because of the weight, size, shape, abilities, braking abilities, etc., of the vehicle.

The main types of transport accidents are:

Vehicle crashes

People being struck or run over by moving vehicles

People falling from vehicles

People struck by objects falling from vehicles, or vehicles overturning.

The analysis of European Statistics on Accidents at Work (ESAW) data reveals that 29% of fatal accidents at work are due to loss of control of means of transport or handling equipment. Thus, improper handling and loss of control over vehicles may cause a severe threat to both the driver and the pedestrians

The major objective of our project is to prevent these types of accidents with some simple and economical means.

To prevent the unexpected reverse motion of an Automobile under gradients and mountain roads.

To protect the heavy load vehicle drivers and fellow Pedestrians from disastrous accidents occurring due to Loss of control and improper handling of equipment.

To ensure the safety of the driver and vehicle on inclined grounds.

To increase the life of brake shoe and to reduce the fuel consumption.

The problem which we taken under consideration in this project was unexpected reverse motion an automobile in gradients and mountain roads.

This problem may occur due to driver’s carelessness or improper handling of the equipment.

‘Employees who drive more than 25,000 miles a year have at least a one in 8,000 chance of dying behind the wheel of their company vehicle’(RoSPA, taken from UK Transport Research Laboratory 2008).

We are eager to provide a simple and economical solution for the above mentioned problem and we had done it as a small prototype for our mini project.

When a normal vehicle is moving on an inclined path in a heavy traffic or if it is stopped on the slope and then suddenly started, it tends to move backwards. This can cause an accident with the vehicle just behind. In the normal running of a vehicle we have to perform three tasks at the same time i.e. disengaging the handbrake, releasing the clutch and at the same time accelerating the car. It can prove to be difficult for a novice driver.

To solve this problem, we make use of a freewheel, which is attached to the differential. This freewheel is engaged with the help of actuator and is coupled with the bevel gear of the differential. The motion of freewheel is restricted in reverse direction. So, when the vehicle is moving in the forward direction then freewheel also moves in the forward direction, But when the vehicle is moving in reverse direction then the freewheel restricts the reverse motion.

Hence, the accidents can be avoided. Also, freewheel doesn’t have to be disengaged for the vehicle to move in the forward direction. It can move in forward direction without any problem. To move the vehicle in the reverse direction freewheel has to be disengaged. To disengage freewheel an actuator is used.

The proper selection of material for the different part of a machine is the main objective in the fabrication of machine. For a design engineer it is must that he be familiar with the effect, which the manufacturing process and heat treatment have on the properties of materials. The Choice of material for engineering purposes depends upon the following factors:

Availability of the materials.

Suitability of materials for the working condition in service.

The cost of materials.

Physical and chemical properties of material.

Mechanical properties of material.

The selection of the materials depends upon the various types of stresses that are set up during operation. The material selected should with stand it. Another criterion for selection of metal depends upon the type of load because a machine part resist load more easily than a live load and live load more easily than a shock load.

The Materials selected in project for Base plate, motor support, sleeve and shaft is Mild steel

Mild steel is readily available in market.

It is economical to use.

It is available in standard sizes.

It has good mechanical properties i.e. it is easily machined.

It has moderate factor of safety, because factor of safety results in unnecessary wastage of material and heavy selection. Low factor of safety results in unnecessary risk of failure

It has high tensile strength

The modifications that can be done in this project are:-

With the advancement in material technology, the design strength should be so given that the mechanism can work for longer period of time without failure.

A sensor can be put in the car to sense the inclination of the road. If it senses an inclination (which is more than desired) it will engage freewheel automatically.

The project “Anti Reverse Differential” helps in avoiding the reverse motion of the vehicle on the inclined roads and Ghats. Since no complex structures are used in our design, it can be easily use by novice drivers. Thus the mechanism can stop the vehicle from rolling back in hill roads. This would be more helpful for the drivers to drive their cars comfortably in hilly roads and he can take off the car in the uphill without rolling back the car.

[1] Alfred sigl, Sershiem; Germany (1987) ; ”Vehicle with lockable differential” U.S. patent,no 4,671,373 June 1987

[2] Design Data Book(PSG)

[3] Theory of machines by R.S Khurmi & Gupta:- Differential gear of an automobile.

[4] Transport Research Wing, “Road Accidents in India”, Ministry of Road Transport and Highways, India, 2011.

[5] Mahesh shahapuri-Anti-roll back system for manual transmission vehicles (WO 2013024491 A2).