Published on Sep 03, 2023

Automobile pollution is the major source of Pollution. Exhaust gas recirculation (EGR) works by reticulating a portion of an engine's exhaust gas back to the engine cylinders. Exhaust gas is routed back into the combustion chamber because the exhausted air is much hotter than the intake air.Usually, an engine recalculates’ exhaust gas by piping it from the exhaust manifold to the inlet manifold.

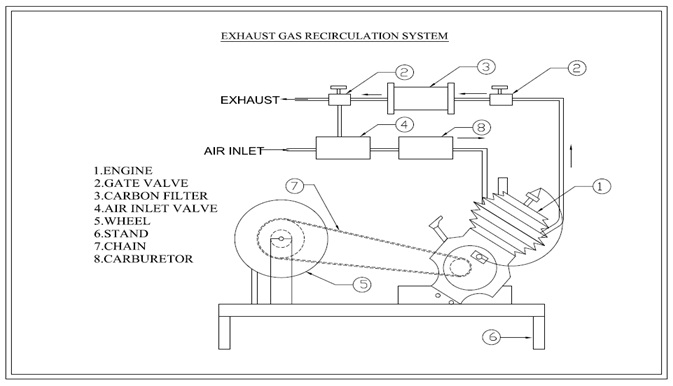

This design is called external EGR. A control valve (EGR Valve) within the circuit regulates and times the gas flow. The exhaust gas is used to rotate the carbon filter with control by gate valve arrangement. Carbon filter used to filter the exhaust gas and pure gas rotate to inlet manifold and unwanted gases are throughout by using gate valve arrangement. Pure gas mixed with inlet air of carburetor. It is also good with regard to economical considerations and engine efficiency. In which the efficiency of the Engine can be increased.

Nitrogen oxide (NOX) emissions can be reduced using internal engine technology by Exhaust gas recirculation some of the exhaust gas, which is then redirected back into the charge air. This results in the reduction of the combustion temperature and less nitrogen oxide is produced. This process is known as exhaust gas recirculation (EGR) and is one of the principal methods used to reduce nitrogen oxide emissions from diesel engines. MTU has been developing this important technology and the functions and components associated with it since the beginning of the 1990s.

The present invention relates to an exhaust gas recirculation system for an engine with a turbocharger.

Recirculation of exhaust gas into the intake gas of an internal combustion engine is widely recognized as a significant method for reducing the production of nitrous oxides (NOx) during the combustion process. The recirculated exhaust gas partially quenches the combustion process and lowers the peak temperature produced during combustion. Since NOx formation is related to peak temperature, recirculation of exhaust gas reduces the amount of NOx formed.

In exhaust gas recirculation, some of the exhaust gas is drawn off from the exhaust system; filter and redirected back into the cylinders (see Figure). Although the exhaust fills the combustion chamber, it is not involved in the combustion reaction that takes place in the cylinder due to its low oxygen content. The speed of the combustion process overall is thus reduced, with the result that the peak flame temperature in the combustion chamber is lowered. This dramatically reduces the production of nitrogen oxides and other emissions.

• Light-Duty Engines.

• Heavy-Duty Engines

• Nonroad Engines

• Marine Engines.

• Two wheeler and four wheeler

• reductions in lubricating oil consumption,

• increases in fuel injection pressure,

• increased use of diesel oxidation catalysts, and

• Increased intake manifold boost pressure.

• Easy combustion

• Emission control