Published on Sep 03, 2023

This is a project we have an implemented for fuel efficiency increased for four wheeler system, which is used flywheel attached on axle. This is a process increased fuel efficiency depend upon the RPM level, so we have to use two flywheel attached for near in wheel on axle system. First starting level given a more amount of energy in axle then going to some towards initially rpm level increased in compared another four wheelers.

This is process only analyse the rpm level whereas we have to use four stroke petrol engine, which is used only cost depend upon that.

Keywords: Flywheel, rpm level increased, four stroke petrol engine.

The flywheel is an old means of storing energy and smoothing out power variations. The potter’s wheel and the spinning wheel are examples of historical uses of flywheels. The focus in this review is on applications where flywheels are used as a significant intermediate energy storage in automotive applications. Several trade-offs are necessary when designing a flywheel system, and the end results vary greatly depending on the requirements of the end application.

Examples exist of power flywheels, such as the ABB short-circuit generator (built in 1933 and still in use today), which can deliver a stunning 4000 MVA and short-circuit currents of 100 kA rms for short durations of time. On the other side of the spectrum, one can find a lightweight energy flywheel with a rotor specific energy of 195 Wh/kg, which is comparable to that of Li-ion batteries. Perhaps the most important trade-off in a flywheel energy storage system is between high power or high energy.

A high-power application is relatively simple seen from a flywheel design perspective. A standard high-power electric machine is fitted with some extra weight to sustain the power for a long enough time. A focus on high energy means that the requirements on the mechanical properties of the rotor puts limits on the power transfer units or suspension. Energy flywheels are a main area of research, since this opens up possibilities for new end applications.

Some end applications, for example a flywheel power buffer in a hybrid bus or a Formula 1 flywheel, will release the stored energy relatively soon after charging. This requires an optimization focus on the round trip efficiency (sometimes called AC-AC efficiency), computed as the fraction of input and available output energy.

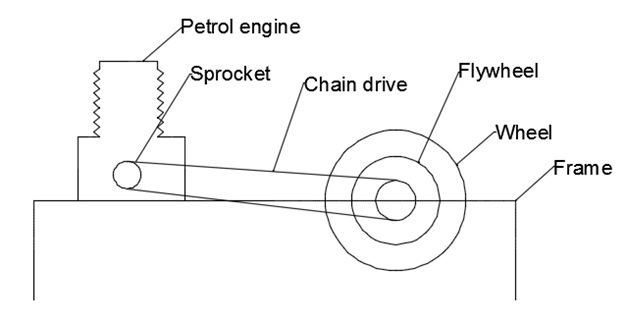

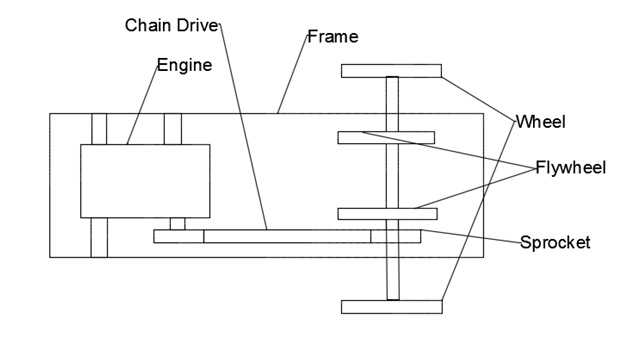

This is a project only attached flywheel getting fuel efficiency increased in four-wheel system, we have to used four stroke petrol engine attached frame and two wheel contain of axle shaft instant of flywheel attached near in wheel so, when you start the engine most of power transmitted to the axle, which is used chain drive mechanism.

The engine while start it rpm level decreased in first gear going on second, third and fourth gear rpm level going to max level is compared another engine.

• Simple process and maintenance easy to handled.

• Fuel efficiency increased,

• RPM level going to high,

• Cost wise is low.

• Light weight four wheelers.

• Heavy weight four wheelers.

• Two wheelers.