Published on Feb 28, 2025

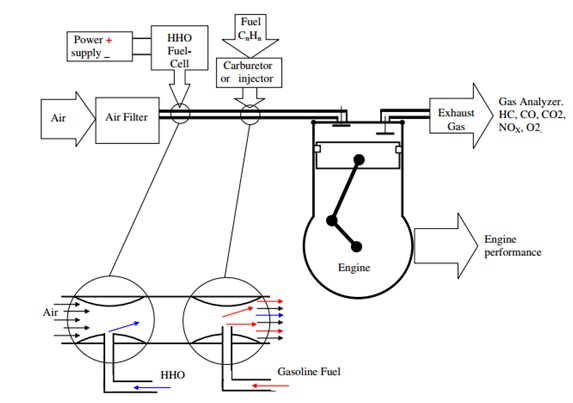

Reducing the emission pollution associated with oil combustion is gaining an increasing interest worldwide. Recently, Brown’s gas (HHO gas) has been introduced as an alternative clean source of energy. A system to generate HHO gas has been built and integrated with four stroke engine. The results show that a mixture of HHO, air, and gasoline cause a reduction in the concentration of emission pollutant constituents and an enhancement in engine efficiency.

The emission tests have been done with varying the engine speed. The results show that nitrogen monoxide (NO) and nitrogen oxides (NOX) have been reduced to about 50% when a mixture of HHO, air, and fuel was used. Moreover, the carbon monoxide concentration has been reduced to about 20%. Also a reduction in fuel consumption has been noticed and it ranges between 20% and 30%.

Global warming is considered one of the major problems the scientific community has to face. Many theories refer to the increase of exhaust gases concentration in the atmosphere as one of the major causes of the global warming. Industrial plants and automobiles are the major source of the exhaust gases. Since they utilize the power associated with oil combustion as energy source. Emissions are simply the exhaust or leftovers of combustion coming out of an engine.

An emissions test is normally done with a probe placed into the exhaust stream. Every road going vehicle has certain clean requirements that it is required to meet. The emission sampler, which is known as gas analysers, measures five types of gases. These gases are HC, NOX, O2, CO, and CO2. HC which refers to hydrocarbons, are simply another term for unburned fuel that makes its way through the engine and out the exhaust.

Smog intensity is proportional to the amount of HC’s in the exhaust. HC’s is also considered hazardous when inhaled. NOXrefers to oxides of Nitrogen. High NOXemission is usually noticed with highly heated and compressed air that has nitrogen in it.NOXis another bad emission to breath at high levels. O2which is unburned oxygen in the exhaust is also measured. Although O2is obviously not bad, it is tested to better understand the combustion characteristics.

Knowing the percentage of oxygen in the exhaust one may estimate the air/fuel ratio ofthe engine as it runs. CO and CO2refer to carbon monoxide and carbon dioxide respectively.Odourless CO causes headaches and eventually death by holdup O2from the human body, if it exists in high quantities. CO2is present in the air in large amounts contribute to greenhouse effect and consequently global warming. HC’s are usually the worst problem for vehicle engines.

FC is a fuel supply device containing several parts that demonstrate the real possibility of how hydrogen can be used as a 100% clean fuel for cars in future. Yull Brown patent, in 1977, a techniqueto generate HHO gas based on electrolysis process. Research on FC is currently going on with main target is to enhance the fuel cell performance and/or reduce the fuel size [18–30]. The fuel cell used in this research is basically an electrolyte cell which decomposes distilled water (H2O) into HHO.

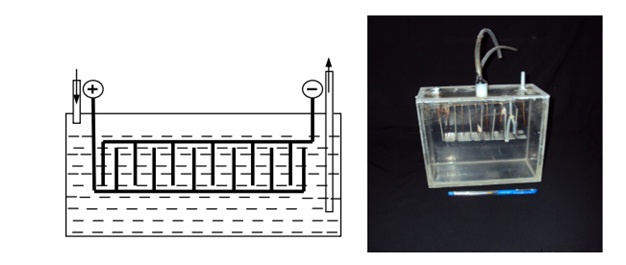

Heat is generated due to this electrolysis process so a sodium bicarbonate may be added gradually to accelerate the decomposing of H2O into HHO and assure control of the heat generation. HHO gas generated, in electrolysis process, due to the separation to water molecules H–HO. It has high potential energy, the caloric value of HHO gas is three times that of gasoline. Plates of stainless steel-grade 316-L are used as the cell plates.

The cell plates have an anode and cathode. Both of them made of the same materials. As a result of experience stainless steel grade 302 and 304 for the cathode (the minus volt wire) may be used but grade 316-L is essential for the anode. The electric current entered the anode and then passes to the cathode through the electrolyte.

The cell plates are arranged inside a Plexiglas box supplied by the required fittings and piping. The input of the cell is distilled water and sodium bicarbonate which is used as an electrolyte. The output gas (HHO) can easily be injected into the combustion chambers in order to spark and burn.

• HHO cell may be integrated easily with existing engine systems.

• The combustion efficiency has been enhanced when HHO gas has been introduced to the air/fuel mixture, consequently reducing fuel consumption.

• The concentration of nitrogen oxide has been reduced to almost 50% on average when HHO is introduced to the system.

• When HHO is introduced to the system, the average concentration of carbon monoxide has been reduced to almost 20% of the case where air/fuel mixture was used (no HHO).

• The NOXaverage concentration has been reduced to about 54% of the case where HHO was not introduced.

• HC concentration is highly affected by the engine speed and the presence of HHO gas.