Published on Sep 03, 2023

Scrap consists of recyclable materials left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap has monetary value, especially recovered metals, and non-metallic materials are also recovered for recycling.

The intention of this mechanical engineering project is to fabricate a scrap collecting robot. Since complete automation is very complex and even research facilities haven’t come up with one, you better design one that is operated via a remote control which is either wireless or not.

This robot is 4 wheeled with an arm to collect scrap materials. It also can move over small obstacles with the support of the arm.Though this project may sometimes look simple, it requires much effort to actually make one working model. In existing we have some scrap collecting machine which is manual and take more time to complete. If we go to automation product, cost will be more and it is difficult to buy.

In this project we propose the model scrap collector which is completely different from existing model and it works on mechanical components so it is comparatively low cost than other full electronic based scrap collector. The attractive feature of this scrap collector is it works by the energy stored by solar energy. It is a renewable sources of energy.

Sensor operating electronic scrap collector

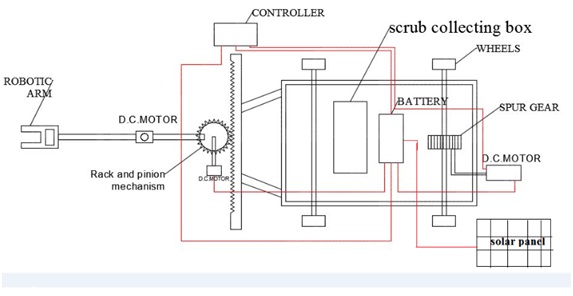

Scrap collector is the machine which collects waste materials and use it for future need. This mechanical scrap collector is works on the basis of solar energy which stores in the battery. We use solar panel to collect the solar energy. The collected solar energy is given to three D.C motors which driven the whole vehicle. D.C motor1 which is attached to the backside of the wheel is used to run the wheel by rotating spur gears.

D.C motor2 which is connected to the rack and pinion attachment is used to collect the scraps in vertical directions i.e., left and right. Rack and pinion mechanism is used to convert vertical to horizontal and horizontal to vertical vice-versa. D.C motor3 is used to operate the arm of the robot and we can just lift the arm and scrap can be put into scrap collecting box. Controller is used to control the movements of the vehicle in appropriate direction.

• Renewable energy.

• Simple mechanical construction. No need of much electronic components.

• Low cost comparing to electronic scrap collector.

• Takes less time to complete the work.

• Reliable.

• Low power.

• Compact size.

• Flexible i.e., move in appropriate direction.

• No need of sensors.

• Used in manufacturing industries.

• Automobile applications.

• Home applications.