Published on Sep 03, 2023

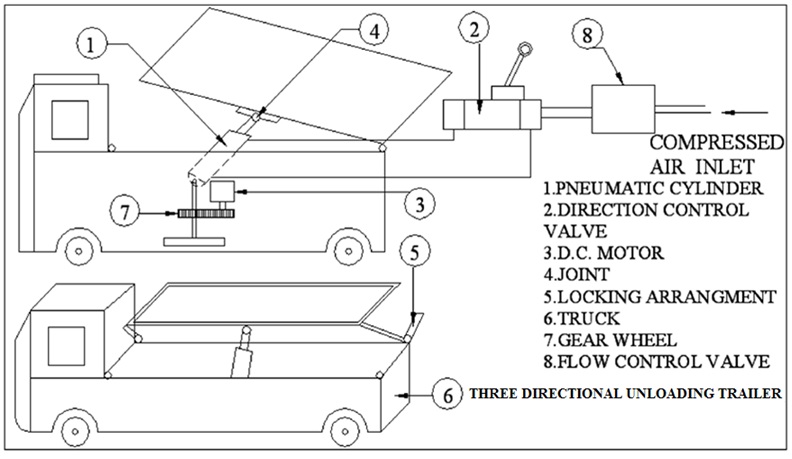

This project work titled “Design and fabrication of Three directional unloading trailer” has been conceived having studied the difficulty in unloading the materials. Our survey in the regard in several automobile garages, revealed the facts that mostly some difficult methods were adopted in unloading the materials from the trailer. The trailer will unload the material in only one single direction.

It is difficult to unload the materials in small compact streets and small roads. In our project these are rectified to unload the trailer in all three sides very easily.

Now the project has mainly concentrated on this difficulty, and hence a suitable arrangement has been designed. Such that the vehicles can be unloaded from the trailer in three axes without application of any impact force. By pressing the Direction control valve activated. The compressed air is goes to the pneumatic cylinder through valve. The ram of the pneumatic cylinder acts as a lifting the trailer cabin. The automobile engine drive is coupled to the compressor egine, so that it stores the compressed air when the vehicle running. This compressed air is used to activate the pneumatic cylinder, when the valve is activated.

Automation can be achieved through computers, hydraulics, pneumatics, robotics, etc., of these sources, pneumatics form an attractive medium for low cost automation.

Automation plays an important role in automobile.

Nowadays almost all the automobile vehicle is being atomized in order to product the human being. The automobile vehicle is being atomized for the following reasons.

• To achieve high safety

• To reduce man power

• To increase the efficiency of the vehicle

• To reduce the work load

• To reduce the fatigue of workers

• To high responsibility

• Less Maintenance cost

It requires simple maintenance cares

Checking and cleaning are easy, because of the main parts are screwed.

Handling is easy.

Manual power not required

Repairing is easy.

Replacement of parts is easy.

1. Initial cost is high.

2. Separate air tank or compressor is required.

It is very much useful for Car Owners & Auto-garages.

1) Pneumatic Cylinder Design

2) Gear Ratio Calculation

3) Pneumatic Pressure Calculation

4) Technical Data’s for Construction

Three axis pneumatic modern trailer is a device it can be used to transmit the heavy loads from one place to another using transmission system. Normally existing system trailer is cannot rotates the load carrying arrangement, it have only Up and down movement for unloading condition.

In our project we are using the gear arrangement to the bottom of modern trailer body, it have rotary motion to unload the weight and it also have up and down movement that means oscillation movement of the load carrying. Main advantage of the three axis modern trailer is used to unload the weight in easiest manner for three Direction.