Published on Sep 03, 2023

Suspension is the term given to the system of springs, shock absorbers and linkages that connects a vehicle to its wheels and allows relative motion between the two. Suspension systems serve a dual purpose contributing to the vehicle's road holding/handling and braking for good active safety and driving pleasure, and keeping vehicle occupants comfortable and reasonably well isolated from road noise, bumps, and vibrations, etc.

These goals are generally at odds, so the tuning of suspensions involves finding the right compromise. It is important for the suspension to keep the road wheel in contact with the road surface as much as possible, because all the road or ground forces acting on the vehicle do so through the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and rear suspension of a car may be different.

Air brakes are primarily used for heavy duty vehicles such as trucks and buses. Air is supplied to the brakes through an air compressor. The air compressor is usually driven by the crankshaft belt or timing gears. The engine has to do the effort of filling the air reservoir all by itself. This results in a delayed period before the required amount of air is obtained. In case of heavy duty vehicles, a considerable number of vibrating components are present. In order to reduce the load on the engine and to increase the efficiency of the engine an auxiliary air supply is given for air brakes using suspension dampers.

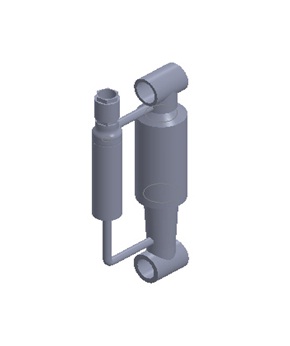

A basic shock absorber consists of a canister (body), a shaft, and a piston. The piston is attached to the shaft that travels up and down inside the body. To hasten rebound, the shock body is filled with either hydraulic fluid petroleum-based oil) or a mixture of hydraulic fluid and gaseous nitrogen (helps dissipate heat built-up due to friction, which may cause foaming, or cavitations, which are undesirable phenomena).

The purpose of shock absorbers is to control the compression and extension (oscillation) of a vehicle’s suspension after hitting a bump or a pothole. To control oscillation in the absence of shocks, the suspension would have to rely on the springs, which have limited oscillative control.

If the shocks don’t create enough resistance, the springs will move the suspension too quickly, allowing violently under-damped motion. Too much oscillation, in other words, will cause your suspension to buck like a mechanical bull. If the shocks create too much resistance, however, the motion will be over-damped. Extra-firm shocks have the same negative effect as extra-stiff springs.

Thus the L-shaped link attached to the movable part of the damper will move. The piston attached to the L-shaped link will move and compress the air inside the cylinder.

The compressed air in the cylinder will move to the reservoir through non return check valve. In case of excessive air or pressure, some amount of air can be released via a relief valve in the reservoir. Thus the required amount of air at the necessary pressure is kept maintained.

• It is used as auxiliary brakes and to minimize the accidents if the primary brakes fail.

• It reduces the slippage of the vehicle on the road.

• A smaller capacity air pump can be used on the engine.

• The load on the engine will be reduced.

• Thus efficiency of the engine will be increased.

• Individually adapted to each vehicle for that decisive plus in handling and driving stability.

• It can be used as an emergency braking system or in case of parking brakes.

• The stored air in the reservoir can be used to cool radiators if in case of overheating.

• The stored air can be used to run pneumatic systems in the vehicle.

• The required amount of air obtained only when the damper moves by a large distance.

• Air cannot be obtained until the desired pressure set in the relief valve is reached.

• This system is effective only in vehicles which use air brakes and more than 6 dampers