Published on Mar 01, 2025

Three wheeler shuttle vehicle is a small foot print electrical vehicle which mainly focuses on transportation in big organization, malls and industries. The main benefits of vehicle are its eco-friendliness and ease in transportation. This vehicle also helps handicapped people for their selftransportation.

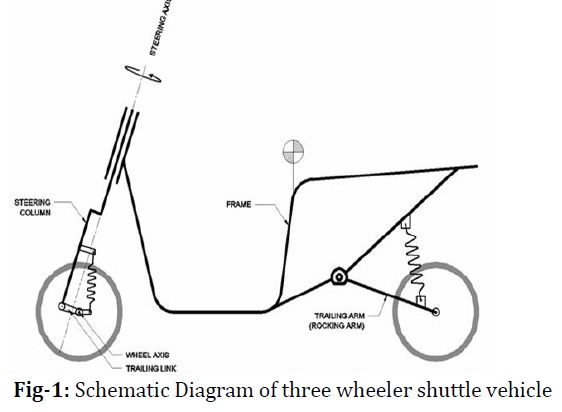

As the present era of huge modernization and competition, related to new advanced techniques in different sector of engineering. So we have tried to add some new trends in it. As we know that, the sources of non-renewable energy are came to vanish so the prices of fuels like petrol, diesel and other fuels are rapidly increasing. As well as, because of heavy industrialization and also number of vehicles on road in India increases. So because of that, pollution rate is also increases. From the exhaust gas of vehicles, numerous hazardous gases such as N2, O2, CO etc. get exhausted into atmosphere causing the pollution which adversely affect on human beings, plants as well as on animal life. Hence, in our project, we built a three wheeler personal transport vehicle called three wheeler shuttle vehicle. It is an electronic vehicle. In this vehicle, balancing is done by extra third wheel instead of balancing circuit.

As the balancing circuit is quite complicated and expensive so we decided to join the third wheel to make it economical. In multinational companies and big scale organizations, the distance between department to department is quite long. Then it may become troublesome for human to travel from one place to another for number of times by walking. Then shuttle vehicle can be used as an option to get over these difficulties. It can also be used for patrolling for police, security purpose in malls. So we thought to build a eco- friendly vehicle. Shuttle vehicle is a personal transport electric vehicle operated by battery. Another purpose of shuttle vehicle is to help the handicapped people for transporting from one place to another.

As the technology is advancing day by day, the human beings are becoming passionate about making innovative things. The companies should build environmentally friendly vehicles which are working in the field of material handling and transportation. There is increase in the demand for green energy powered vehicles due to air and noise pollution and global warming. The main aim of this project is to develop three wheeled shuttle vehicle as a feasibility study. Mr. Dean Kamen invented and released a vehicle named Segway personal transport from which we got inspired and build this vehicle. Segway consist of two wheels arranged axially parallel to each other. The problem of balancing created because of such arrangement of wheels is eliminated by the balancing circuit. For directing purpose different kinds of sensors are used.

In three wheeler shuttle vehicle we have used brushless DC stepper motor of 300watt / 03 hp capacity. The main parts of motor are as following: 4.1.1 Rotor The mechanical power is delivered by rotor which is the moving part of motor. The rotor consists of conductor which generates forces that interact with magnetic field that turn the shaft. Stator holds the conductors and rotor carry permanent magnet.

The Stator is stationary part of rotor, which generally has either windings or permanent magnets.

Air gap is in between rotor and stator. The air gap plays an important role and it is kept a small as possible as the performance of motor is affected by large air gap.

Today commonly used batteries are Dry cell batteries which are used in most of the electrical appliances. There is a paste electrolyte in a dry cell which will allow the required quantity of moisture from which current will flow. Without spilling, a dry cell can operate in any orientation, as it contains no liquid, so the dry cell batteries can be used for portable equipment.

Zinc–carbon battery is a commonly used dry cell, also known as the dry Leclanché cell, having 1.5V, the same as the alkaline battery. Zinc anode is in the form of cylindrical pot with a carbon cathode in the form of a central rod. Ammonium chloride is a electrolyte which is in the form of paste which is next to the anode (zinc). E-bikes comprises of electric motors, basic controls and rechargeable batteries. Commonly used batteries are sealed lead-acid (SLA), lithium-ion polymer (Li-ion nickel-cadmium (NiCad), nickel-metal hydride (NiMH), and lithium-iron phosphate (LiFePO4). Performance of batteries varies according to the specifications like voltage, weight, total charge capacity (amp hours), the number of charging cycles before performance degrades as well as ability to handle over-voltage charging conditions.

The main function of a controller is to read the throttle setting after certain time period and adjustment of current supplied and this method is called as ‘Pulse width modulation technique’ (PWM). Some secondary purposes of the controller are:

Low-voltage cutoff: If the battery voltage is too low controller shuts down the motor which does not allow over discharge of the battery.

Over-temperature cutoff: The controller maintains the required temperature of the FET transistor and hence transistor remains safe.

Over-current cutoff: If the large current is being supplied to the motor as well as transistor then controller reduces the current and protects both motor and transistor.

The speed and acceleration of electric vehicle is controlled by controller which operates between batteries and motor it is nothing like but the carburetor in the IC engine. The controller converts dc into ac and draws it to the battery and also energy flow is regulated. 4.4 Convertor It acts as a voltage reducer, which converts the supply given by the batteries i.e. 48 volts into 12 volts. This current is supplied to accessories of vehicle such as headlights, horns etc.

The material used for chassis of the vehicle is steel.

While designing this chassis we considered following factors-

a. Stress concentration.

b. Aerodynamic shape.

c. Caster angle.

d. Compact size.

e. Short turning radius.

Distance between front and rear wheel = 100 mm.

Distance between two rear wheels = 60 mm.

Caster angle = 15º.

Turning radius = 1200 mm

Overall Footprint: 40cm × 40 cm

Ground Clearance: 10 cm

Wheel Diameter: 43cm

Weight: 55kg

Rider Capacity: 125kg

Peak Motor Power: 300watt / 03 hp

Theoretical Top Speed: 25 kmph

Battery: 12V

Anyone who’s ever ridden a bicycle with a dynamo light should get an idea of how electric bikes work. With a dynamo light the kinetic energy of the spinning tyres turns the dynamo, transferring energy and ultimately powering the light. Electric bikes work oppositely. A ‘dynamo’ of sorts, in this case a battery, produces energy that transfers to kinetic energy in the tyres and moves them forwards.

A typical battery in an electric bike will have approximately a quarter of the power of a toaster, 200-350W. The batteries need to be able to store as much power as possible, and for this reason lithium-ion batteries (like the ones in your mobile phone and computer) are most commonly used. They can often be taken out of the bike and recharged by being plugged into a standard mains plug socket, and most bikes will give upwards of 80km (50-miles) of battery-assisted riding. The battery powers the motor, which will increase the speed by about double what the rider is pedaling, up to a top speed of 32kph (although the legal limit for an electric powered bicycle is about 30kph, or 15mph).

The motor can either assist the pedaling of the cyclist or provide separate power controlled by a throttle on the handlebar. The batteries of our vehicle can be recharged by external source available in houses. The power from the batteries is given to motor through the controller. When we accelerate the lever, then the supply from batteries is given to motor through controller in controlled manner as per the acceleration. When we fully accelerate the lever the maximum supply is given to motor and vehicle runs at its maximum speed. For operating the accessories it is necessary to reduce the voltage, for avoiding the damages of accessories such as overheating and blowing off. Hence here we use a converter. Converter acts as a voltage reducer, which converts the supply given by the batteries i.e. 48 volts into 12 volts. This current is supplied to accessories of vehicle such as headlights, horns etc.

a) No pollution- As there is no emission of harmful gasses such as Co, Co2, HC, N, carbon particles etc. hence there is no air pollution. It also does not raise the problem of global warming. As an electric bike does not consist of any engine, so there is no question of noise pollution.

b) Economical- Now a days the costs are going on increasing day by day, and this bike does not uses any fuel as well as for full charging it utilizes power less than 1 unit, therefore from all points of view this bike is economical to use.

c) Less maintenance As this vehicle is consist of very less parts as we compare to conventional bikes therefore the maintenance required is low.

d) Short turning radius- As the design of vehicle is compact, so the turning radius is less i.e. 1200 mm, so it can travel easily in any congested and compact space.

e) Optimum average- The average of vehicle is quiet satisfactory i.e. 45 km.

a) As we are well known that the sources of fossil fuels are going to be vanish in next few decades, hence the electric bike will experience the period of boom. Hence we can say that, this vehicle may have very bright future.

b) The efficiency of this vehicle can be raised by adding solar panel or alternator to charge batteries. By enforcing the alternator in the vehicle, we can charge batteries during travelling. So there is no need to charge batteries frequently.

c) We can also provide the reversing arrangement.

From above paper we can conclude that this vehicle is quite suitable for almost all the humans. By referring to above advantages, the vehicle is affordable to middle class person also, because the cost of vehicle is optimum. “As the current increasing volume of car transportation rising the health problem as well as environmental issues, hence this vehicle focus the technology that enables the manufacturing, launching and sustainable implementation of 3 wheel battery operated shuttle vehicle in Indian market.”

Mr. Shubham S. Limkar, Mr. Rajvardhan C. Ambupe, Mr. Abhijeet Y. Kedge, Mr. Ketan S. Kumbhar, Mr. Pratik S. Patil

[1]Mikael Arvidsson Jonas Karlsson, “Design And Construction And Verification Of A Self-Balancing Vehicle”, Department of Signals and Systems Chalmers University of Technology Göteborg, Sweden, 2012 EX050/2012

[2] M.Thompson, J.Beula Julietta Mary, “Design And Fabrication Of Fail Safe Segway Personal Transporter” Vol. 2, Issue 1, pp: (78-82), Month: April 2014 - September 2014, Available at: www.researchpublish.com

[3] Sadhana Pai, Jayesh Yadav, Rupesh Ramane, Pooja Pangare, Aniket Paranjpe, “Design Of Segway Personal Transporter”, Volume 1, Special Issue , Vivruti 2015. Impact Factor: 1.036, Science Central Value: 26.54