Published on Mar 01, 2025

The Vacuum Assisted Climber is a new approach for climbing vertical surfaces. Unlike typical grappling hooks used today, it uses the principle of a vacuum to rapidly scale walls. This suction is produced by spinning impellers within each suction blower, which removes air from a sealed area. The pressure release mechanism helps the climber to reach the next higher step. Foot stirrups are used by the climber, which allows the strength of the climber’s legs to lift his body reducing arm fatigue, allowing rapid ascension of any climbable wall.

The overall desirables to accomplish in this project are to make a new system that is lightweight and easy to manufacture. It also finds many applications in military operations, rescue operations and domestic purposes.

Conventional methods of climbing include ladders and grappling hooks. A ladder is a vertical or inclined set of rungs or steps. The most common injury made by ladder climbers is bruising from falling off a ladder, but bone fractures are common and head injuries are also likely, depending on the nature of the accident. If a leaning ladder is placed at the wrong angle, the risk of a fall is greatly increased.

A grappling hook is a device with multiple hooks, attached to a rope. It is thrown, dropped, sunk, projected, or fastened directly by hand to where at least one hook may catch and hold. Generally, grappling hooks are used to temporarily secure one end of a rope. Common injuries include wrist cartilage and ligament tears, hand fractures wrist fracture, wrist sprain, and elbow fractures.

The other injuries to the upper extremity occur from overuse or repetitive use. The project principle is that, if we create a region where the air is sucked out, like in a vacuum, then the atmospheric pressure will act on that region generating large amount of force. This force will be sufficient to withstand the weight of the average human. The aim of our project is to give an alternative method to scale the vertical walls. It has to improve the ease of climbing and improve the ergonomic factors.

Rohit Jaiswal, Ravi Bhardwaj and Rajesh Anant studied about the braking system that uses a vacuum pump for creating vacuum in the brake pipe. Vacuum brakes are first used in place of the air brake in railway locomotives. Nowadays most of the light vehicles are fitted with vacuum-assisted hydraulic braking system where vacuum is created from the engine which reduces the driver effort on foot pedal.

Kenneth Richter and Brent Knudson studied that proximal extremity wounds in diabetic patients are often difficult to heal. Negative-pressure wound therapy (NPWT) with a vacuum-assisted closure (VAC) system has been successfully used in the management of various wounds on the trunk and distal extremities, including diabetic foot ulcers.

Noo Li Jeon, Insung S. and Choi, Bing Xu reported about a procedure that allows rapid micropatterning of polymers over rigid and flexible substrates. This procedure utilizes a variation of micromolding in capillaries (MIMIC) to vacuum assisted MIMIC to achieve rapid filling of capillaries.

El-Sherbiny Y.M, Hasouna A.T and Ali W.Y presented a study of the friction coefficient of rubber sliding against different types of flooring materials of different surface roughness was investigated under different sliding conditions: dry, water, water/detergent dilution, oil, water/oil dilution. Based on the experiments, it was found out that at dry sliding, friction coefficient decreased with increasing surface roughness.

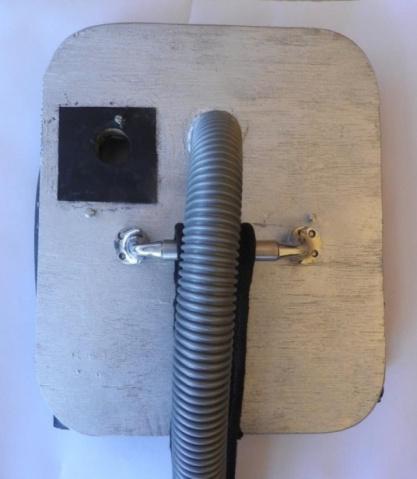

The plywood of 20mm thick was selected due to its light weight and machinability. To create the suction pad, the plywood was cut to the required dimension of 400×300mm. The position of the holes for the handles, suction pipe, and valve release mechanism are marked and using a circular drill, the holes of the required dimensions are cut. The handles are attached to the plywood base using bolts. On the opposite side, the space required for the foam seal is marked and the surface is scored for better adhesive grip. Using rubber adhesive glue, the foam rubber is pasted on the scored surface. On top of the foam rubber, using rubber adhesive glue, high density polypropylene is pasted. The process is repeated to obtain alternate layers of foam and high density rubber. The connector hose is connected to the suction pad using epoxy and left to cure for a day, in order to make it an air tight seal. The corners of the suction pad are chamfered for better handling and aesthetic appeal. Finally, the suction pads are painted in metallic silver color using acrylic epoxy spray paint.

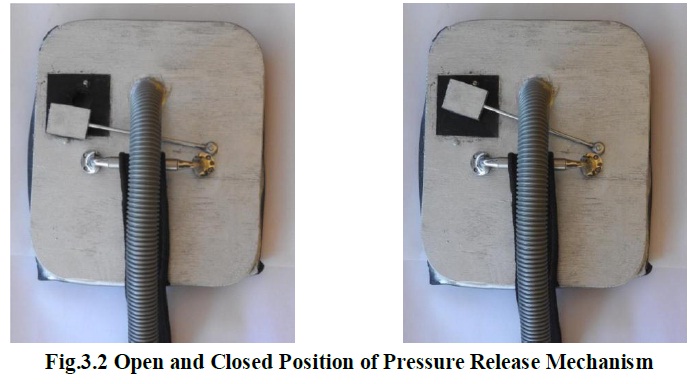

The pressure release mechanism enables the climber to remove the suction pads with ease. The valve is placed above the handle so that the user can operate it without taking his hands off the handle. Rectangular plywood of dimension 50×40mm is fixed to a stainless steel rod of 3mm diameter to create the link. A layer of high density rubber is glued to the side of the rectangular face to obtain a better vacuum seal. The link is fixed to the suction pad using a flat head screw. The screw is provided with a clearance so that it is much easier to operate the valve.

The plywood is cut to required dimensions and the corners and edges are chamfered for better handling and aesthetic appeal. The vacuum motors are sealed at the suction end using a polyvinyl chloride end cap and an orifice is drilled to allow for air flow. The edges of the motor and end cap are sealed using epoxy and left to cure for better strength. An air filter is inserted into the end cap to protect the impellers from dust and other impurities. Using C-clamp, the motors is fixed onto the layered plywood base using bolts. Then, the handsfree harness is attached to the backpack and its other end is connected to the suction pads. Then, the extension cable of 4m length is also attached to it. Finally, the backpack is then painted in metallic silver color using acrylic epoxy spray paint.

For stable and faster climbs, the foot support system was the optimal choice. Since it is exhausting to utilize only the upper body strength for climbing, a foot support system is provided so that the climber experiences less fatigue and better balance. The harness was more flexible, which allowed for easier and faster lateral movement. It should be light weight, and should posses moderate tensile strength. Interwoven polyester fabric is used to prepare the foot supporting harness. The polyester fabric is repeatedly woven to increase the thickness of the band and one end is attached to the suction pad handles.

The climber puts on the backpack, consisting of two vacuum motors and the hose pipe is connected to each suction pad. The suction pad is held on each hand and the vacuum motors are turned ON. The climber locks the release mechanism for both suction pads. The first suction pad is placed on the wall. Due to the negative pressure created, the suction pad will attach firmly to the wall. Then the next suction pad is placed on the wall at a higher distance. For taking the next higher step, the pressure release valve is released on the first suction pad, which allows the atmospheric air to enter into it. So, the climber would able to release the suction pad from the wall. The climber then places the suction pad on the next higher step, by balancing his weight on the other foot harness and handle. The climber releases the valve mechanism on the second suction pad, enabling him to lift the suction pad and place it over the next higher step. Theoretically, the climber can climb the vertical wall through infinite distance. But, for safety reasons, the experiment is conducted upto a height of 10m.

The Vacuum Assisted Climber has many applications. The possible uses for the VAC include:

Military Applications

Rescue Operations

Recreational Use

Household Use

Military applications could include fighting environments where climbing over large obstructions was necessary. Stealthy operations might also be used for Covert Operations.

Rescue tasks could include firefighting situations where accessing the interior of a building is not viable option or could be life threatening to the firefighter. Roofing operations could also use the VAC for a temporary anchor point if the surface cannot be fastened to.

For recreational use, the obvious use would be at a local rock climbing facility or a carnival. The VAC could be sold to the public if proper standardized tests were passed. Small-scale VAC systems could also be built for the young children or teenagers.

The window washing industry might even be able to use the VAC if it seemed feasible. It can also be used for painting purposes, cleaning purpose, etc.

This project is mainly focused on achieving an alternate method of climbing the vertical walls. The project was completely successful as it can lift an average human weight of 60Kg. Climbing mechanics was greatly enhanced by ergonomics, lighter weight, and ease of use. The time of operation is upto 20 minutes. We were able to complete the project within the prescribed time.

The main advantages of the project are:

Can climb vertical walls faster than conventional methods.

Can be able to lift 60Kg.

Handsfree capabilities.

Climb a variety of surfaces. (Glass, Brick, Adobe etc.)

Be able to scale a 10m (or higher) structure.

The major drawbacks of our project include the following:

The operation time is limited to 20minutes, due to high amount of heat produced.

Cannot lift weight more than 60Kg.

The Vacuum Assisted Climber weighs approximately 10Kg.

High noise of the vacuum motors (76dB).

Can climb on flat surfaces only.

Dheeraj Sudesh M, R. Adithya, Selva Manoj R, Sooraj K

[1] Rohit Jaiswal, Ravi Bhardwaj, Rajesh Anant, Prakash Kumar Sen and Shailendra Kumar Bohidar, Study of Vacuum Braking System. IJR 2014;10(1):2348-6848.

[2] Kenneth Richter and Brent Knudson, Vacuum-Assisted Closure Therapy for a Complicated, Open, Above-the-Knee Amputation Wound. Case Report J Am Osteopath Assoc. 2013;113(2):174-176.

[3] Noo Li Jeon, Insung S. Cho, Bing Xu, and George M. Whitesides, Large-Area Patterning by Vacuum-Assisted Micromolding. Advanced Materials 1999;11(11):946-950.

[4] El-Sherbiny Y.M., Hasouna A.T. and Ali W.Y, Friction Coefficient of Rubber Sliding Against Flooring Materials. APRN 2012;07(1):1819-6608.