Published on Mar 01, 2025

Solid waste management has become one of the main issues in both urban and rural areas all over the world. With the progress of civilization, the waste generated become more complicated in nature. People are in the habit of throwing the waste into one bin and making it difficult to segregate for recycling. So, it is necessary to devise a means of sorting-out the components of domestic waste for reusing or recycling based on the type of waste material. There are sophisticated waste management plants available in the developed countries with huge investment.

But the technology available in developed countries is hard to implement in India in this sector due to funds limitation, different demographic profile of users, general education and awareness level in the community regarding waste and cost of running sophisticated waste plants. Cities in developing countries hardly spend more than 0.5% of their per capita gross national productivity (GNP) on urban waste services, which covers only about one-third of overall cost of waste management. A simple and low cost waste sorting machine for the developing countries like India is an urgent need.

A mechanical sorting system was fabricated and developed for segregation of mixed household waste (especially paper, plastics, metallic and non-metallic materials) that are left uncollected from domestic waste due to lack of efficient and economical waste sorting. The testing and performance evaluation of the machine was also carried out. The machine was able to sort municipal dry wastes with an average overall efficiency of 55.60%.

Solid waste management has become one of the main issues in both urban and rural areas all over the world. With the progress of civilization, the waste generated become more complicated in nature. It is an undeniable fact that the environment has been engulfed in filth. This filth comprises of the garbage and waste generated in homes, workplace and industrial setups. Most of this waste has found its way into the streets, gutters, in and around the homes. Now-a-days the wastes are dumped as landfill, in some cases some chemicals are added to it to decompose the waste and the major problem of solid waste disposal is plastic separation and they are separated manually and recycled[4]. Domestic waste collection, sorting and disposal are major problems in many countries.

Garbage needs to be sorted into various components and each of such components like textile materials; polythene, foodstuffs, metals and non-metallic would then have to be handled separately at the disposal or recycling site. Such a process required a certain degree of literacy, discipline and certain basic equipment, for example separate collector bins or sorting bags. Currently, most garbage collection is done by depositing everything into a single container from where they are hauled to be dumped in landfills or burnt in incinerators.

Thus sincere efforts to handle an upcoming disaster are to be coordinated for reducing waste generation, and also its effective disposal, involving primary collection, segregation, recycling to the extent possible and treatment through appropriate technology to reduce their harmful effects to a reasonably acceptable level. The solid waste characteristics reveals that in India the organic fraction of the waste makes up 40-85% of the waste (National Solid Waste Association of India, 2003) depending on income and lifestyle of the population. By recycling this, a significant contribution could be made towards reduction of volume of the waste materials.

The following considerations were made when fabricating the waste sorting machine.

It should replace manual method of sorting waste.

The component parts must be easily available and replaceable in case of any damage or failure.

The operation of the machine is easy to understand.

The equipment should be made with readily and easily available materials.

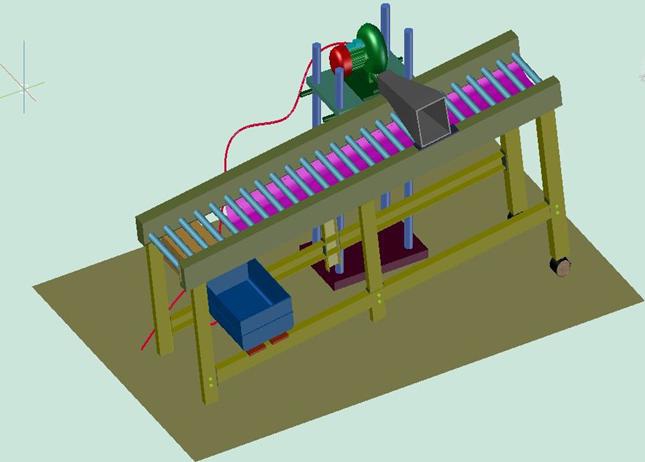

The conveyor is of decline roller conveyor type with an angle of declination 9o and the angle of repose of 33o is provided for the discharge hopper which has been attached below the roller chassis. Components of conveyor are as follows:

Conveyor length = 310 cm

Length of each roller = 52 cm

Inclination of roller conveyor = 9o

Co-efficient of friction of roller = 0.20

Speed of roller = 108 r.p.m

Inclination of discharge hopper = 33o

Air is forced through a channel by an air blower to separate lightweight materials from the waste. The force delivered by the stream of flow should overcome the weight of the light weight material to ensure that the material is moved by the stream away from heavier materials. The average mass per unit area of light materials is assumed to be 400g/m2based on the maximum weight of polythene bag

The weight of the material is thus W = (mA) g

Where, m is the mass per unit area of the material, A is taken to be the cross sectional area of the channel and g is the acceleration due to gravity.

Hence, W = 0.40 × (0.19 × 0.18) × 9.81

= 0.1342 N

The waste sorting machine consists of a roller conveyor frame through which the waste is fed through, a blower and air channel through which the lightweight materials are separated from the waste matrix. The small size waste moves by gravity through the rollers gap were collected at collector bin-1 through discharge hopper. The left over waste materials are carried towards the blower which blows off lighter waste materials like plastic, polythene bags etc. into the collecting outlet bin-2.

The waste materials which were not blown off by the air stream rolls on the conveyor and collected at collector bin-3. So, the machine can sort the mixed waste into three categories of wastes. The initial co-efficient of friction of the roller was 0.20. But it could not provide the required frictional force to carry away the wastes along with it to the desired destination point. So, a little modification was made by wrapping rubber tube for vehicle on the surface of the rollers. Hence, the co-efficient of friction has been change to 0.65 after which provided the required frictional force for the purpose.

The waste used for testing the machine was collected from the temporary storage bins of Games village building A-12. It composed of perusable materials, paper, plastics, nylon, metals and other materials. Hence, it had the characteristics of a typical municipal mixed waste stream. Waste samples with masses of 1.20 kg, 1.50 kg and 1.80 kg were used during the test. The masses of the materials that were sorted at each level were obtained and the ratios of those masses to the initial masses of the mixed waste were evaluated. This was done for three replicates.

The mixed dry waste are fed on roller conveyor, small size materials are pass through the gap between the roller by gravity and will be collected at the collector bin-1 (phase-I). The conveyor carries away the left over pass through the air blower which blows off lighter waste materials like plastic, polythene into a collector bin-2 (phase-II) outlet. And the materials which cannot be blown off by the blower are rolled down and collected in a collector bin-3 (phase-III) outlet. So, the machine can sort the mixed waste into three categories of wastes.

To determine the performance of the machine, the following records were taken from the sorting trials:

Weight of whole material feed = F

Weight of small size material = W1

Weight of light material = W2

Weight of material conveyed to the air duct = F2

Weight of material collected at separation unit 1 = U1

Weight of material collected at separation unit 2 = U2

Weight of desire material recovered at separation unit 1 = Ws

Weight of desire material recovered at separation unit 2 = WL

Weight fraction of desire material recovered at separation unit 1= Wu1

Weight fraction of desire material recovered at separation unit 2= Wu2

Weight fraction of small size material in feed = Wf1

Weight fraction of light material conveyed to the air duct = Wf2

Weight of light material conveyed to the air duct = WL2

Studies revealed that there are many shortcomings in the existing practices followed for the management of municipal solid waste. There is inadequate segregation system and awareness among the people as well. To overcome the deficiencies in the existing systems, stress on segregation using machinery and design of such segregation devices is required. The waste sorting machine is able to sort wastes into light weight and heavy materials with an average overall efficiency of 55.60%. This would increase the recycling rate and also decrease the amount of waste disposed into the landfills. Such type of waste sorting machine which are simple in design could be an answer to the struggling municipalities all over the country.

Pradip Baishya, Shanjenbam Brojendro Singh, D.K. Mahanta

[1].Bupe Mwanza and Anthony Phiri. “Design of a waste management model using integrated solid waste management” International Journal of Water Resources and Environmental Engineering Vol. 5(2), pp. 110-118, February 2013.

[2].F.R. Falayi, B.O. Adetuyi. “Development of Small Scale Municipal Waste Sorter” Journal of Engineering and Applied Sciences 2 (11): 1640-1645, 2007.

[3]. Ijagbemi Christiana.O, Adepo S. Olusegun, 2014 “Design, Development and Evaluation of a Small Scale Kitchen Waste Composting Machine”. International organization of Scientific Research (IOSR) Journal of Engineering (IOSRJEN) www.iosrjen.orgISSN (e): 2250-3021, ISSN (p): 2278-8719 Vol. 04, Issue 04 (April. 2014), V6 PP 29-33.

[4].Joice Johny, Abin Joy, Della Sunny, Basil M Joseph4 & Shaji M Jamal. “Automatic Plastic Separating Technology for Solid Waste Disposal” .International Journal of Civil, Structural, Environmental and Infrastructure Engineering Research and Development (IJCSEIERD) ISSN 2249-6866 Vol. 3, Issue 2, Jun 2013, 99-108.