Published on Feb 28, 2025

The technology of pneumatics has gained tremendous importance in the field of workplace rationalization and automation from old-fashioned timber works and coal mines to modern machine shops and space robots. It is therefore important that technicians and engineers should have a good knowledge of pneumatic system, air operated valves and accessories. The air is compressed in an air compressor and from the compressor plant the flow medium is transmitted to the pneumatic cylinder through a well laid pipe line system.

To maintain optimum efficiency of pneumatic system, it is of vital importance that pressure drop between generation and consumption of compressed air is kept very low.

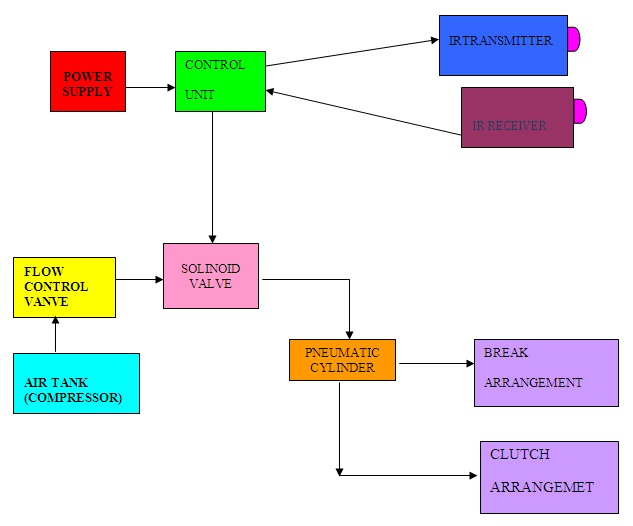

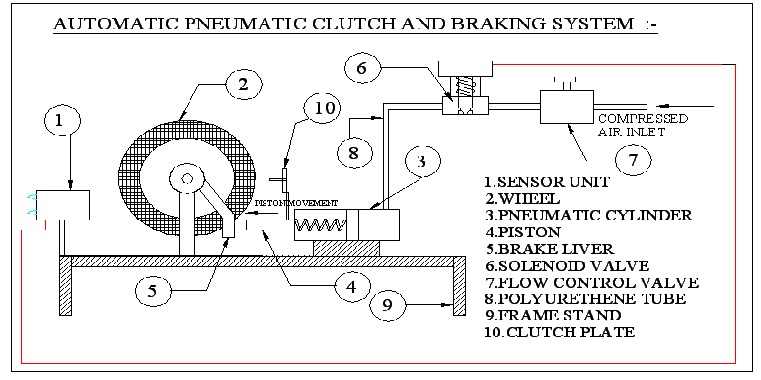

The aim is to design and develop a control system based an intelligent electronically controlled automotive braking and clutch system is called “INTELLIGENT BRAKING AND CLUTCH SYSTEM”. Sensor Operated Pneumatic Brake and clutch is consisting of IR transmitter and Receiver circuit, Control Unit, Pneumatic breaking system. The IR sensor is used to detect the obstacle. There is any obstacle in the path, the IR sensor senses the obstacle and giving the control signal to the breaking and clutch system. The pneumatic breaking and clutch system is used to break and clutch the system.

We have pleasure in introducing our new project “AUTOMATIC PNEUMATIC CLUTCH AND BRAKING SYSTEM”, which is fully equipped by IR sensors circuit and Pneumatic breaking circuit.

It is a genuine project which is fully equipped and designed for Automobile vehicles. This forms an integral part of best quality. This product underwent strenuous test in our Automobile vehicles and it is good.

The “PNEUMATIC BRAKEING CIRCUIT” can stop the vehicle within 2 to 3 seconds running at a speed of 50 KM. The intelligent breaking system is a fully automation project. This is an era of automation where it is broadly defined as replacement of manual effort by mechanical power in all degrees of automation. The operation remains an essential part of the system although with changing demands on physical input as the degree of mechanization is increased.

Degrees of automation are of two types, viz.

Full automation.

Semi automation.

In semi automation a combination of manual effort and mechanical power is required whereas in full automation human participation is very negligible.

The IR TRANSMITTER circuit is to transmitter the Infra-Red rays. If any obstacle is there in a path, the Infra-Red rays reflected. This reflected Infra-Red rays are received by the receiver circuit is called “IR RECEIVER”.

The IR receiver circuit receives the reflected IR rays and giving the control signal to the control circuit. The control circuit is used to activate the solenoid valve. The operating principle of solenoid valve is already explained in the above chapter.

For automobile application

Industrial application

Brake cost will be less.

Free from wear adjustment.

Less power consumption

Less skill technicians is sufficient to operate.

It gives simplified operation.

Installation is simplified very much.

To avoid other burnable interactions viz.… (Diaphragm) is not used.

Less time and more profit.

Additional cost requires doing the automation

Free from wear adjustment