Published on Mar 01, 2025

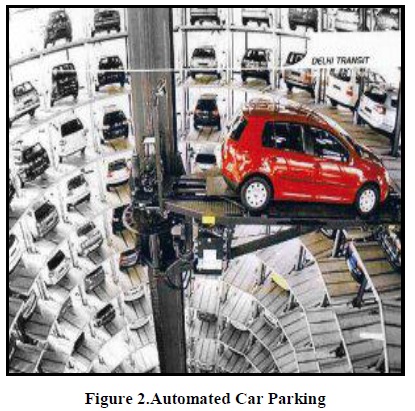

This project deals with manufacture of a Prototype of Vertical Car Parking System. This system has been implemented to reduce the excess use of land space which is already very scarce in metro cities. Different types of vehicle parking are applied worldwide namely Multi-level Automated Car Parking, Automated Car Parking System, and Rotary Parking System. The present project work is aimed to develop a scale down working model of a car parking system for parking cars within a large parking area. The chain and sprocket mechanism is used for driving the parking platform.

This total prototype is powered by a D.C motor. When the car comes on the ramp the switch will be activated and the bucket comes to carry the vehicle. When the switch will be operated by the operator, sprockets starts to rotate and the new space will be adjusted for new vehicle. Planners, developers, architects are finding out solutions to tackle this problem of parking, so we took this opportunity to bring the technology of automated parking to where it is needed.

The first question we are facing when we explaining the project is, “When your project is about parking system which involves some type of lifting mechanism then why don’t you build a multilevel parking system?” So we would like to introduce our project answering that question showing different types of parking as of now which are widely used and the reasons why we had to make this choice from them, in the field of technology everyday a new technique is launched. It has its own characteristics due to which we have to adopt it. Today is the world of new technology which we have to take in practice.

These advanced automatic parking systems are extraordinarily well designed, tested and constructed. They are being used worldwide in totally automated locations, where speed and reliability is critical. The advantages are clear. The systems are scalable and adapt to virtually any architectural foot print. They hold as many as twice any vehicles as similarly sized conventional garages. What’s more they are fast, efficient and environmentally sound.

Customize application suitable for various types of landscapes and buildings Structures available below the ground. Ease control by soft touch on the operation panel screen. When a vehicle stops in front of the entrance, automatically door opens and trolley transfers the vehicle to parking cell. Misleading of this solution is it should be undergrounded. By this investment increases and lot much space utilization is to be made.

The driver will pull the car onto a computer- controlled pallet, turn it off, and get out. The pallet is then lowered into the abyss of parking spaces, much like a freight elevator for cars, except it can also move sideways, not just up and down. There's an array of laser sensors that let the system know if the car doesn't fit on the pallet (although it's big enough to fit a mid-sized SUV),.

The system retrieves the car when the driver returns, although this might take some time and creative manoeuvring. Cars are parked two deep in some spots, so a specially tailored software system has to figure out the logistics of shuffling the various vehicles around as needed to retrieve a specific car. And for those, like me, who find it difficult to turn their vehicle around after pulling out of a space, there's an underground turntable that turns the car around before it is lifted to the surface, so the car is facing out into the driveway, ready to go. Backing out of garages or parking spaces is one of the most common causes of accidents.

A multi-level car parking is essentially a building with number of floors or layers for the cars to be parked. The different levels are accessed through interior or exterior ramps. An automated car parking has mechanized lifts which transport the car to the different levels. Therefore, these car parks need less building volume and less ground space and thus save on the cost of the building. It also does away the need for employing too many personal to monitor the place. In an automated car parking, the cars are left at the entrance and are further transported inside the building by robot trolley. Similarly, they are retrieved by the trolley and placed at the exit for the owner to drive away.

The space for parking 3 cars can hold more than 9 cars.

It adopts rotating for mechanism so as to minimize the vibration and noise.

Flexible operation.

No caretaker is needed, key pressing operation

. High safety, complete inspecting device

Stable and reliable It is simple to operate with the driver parking and leaving the vehicle in the system at the ground level.

Once the driver leaves the incorporated safety zone the vehicle is automatically parked by the system rotating to lift the parked car away from the bottom central position. This leaves an empty parking space available at the ground level for the next car to be parked on. The parked car is easily retrieved by pushing the button for the relevant position number the car is parked on.

This causes the required car to rotate down to ground level ready for the driver to enter the safety zone and reverse the car out of the system. Except vertical car parking system all other systems use a large ground area, vertical car parking system is developed to utilize maximum vertical area in the available minimum ground area. It is quite successful when installed in busy areas which are well established and are suffering with shortage of area for parking. Although the construction of this system seems to be easy, it will be par from understanding without the knowledge of materials, chains, sprockets, bearings, and machining operations, kinematic and dynamic mechanisms Imagine the time that automatic smart parking systems would save you.

Every time you enter your office building you have to find a parking space and spend time walking in and out of the lot as well. Imagine how much time it is costing you. Even if you just spend 5 minutes a day to park that translates to you spending more than a whole day just parking every year. If you calculate the time you spend walking in and out of the parking lot, searching for space and such it will be easily more than the above amount. A fully automated system mimics a futuristic assembly line structure where the cars are moved to an empty platform. The platform under the car moves to a designated spot and all the other platforms are arranged so that no cars are stuck.

You are able to keep track of the entire structure and spend virtually no time driving the car in the parking you. You simply drop off the car at the entrance and pick up on your way out. Aside from the comfort that the automation brings you can also save space through incorporating the park lift system as well. Through this we are able to utilize the vertical space in a parking lot that is usually wasted. You are also able to customize each stack parker so that you can fit different sized cars in each of the different slots. It would be meaningless to have all stack parkers adjusted to the height of a SUV when you can have different sets where you can park 2 SUVs or 3 regular sedans

During this period detail market survey has been done to learn available parking systems and their utility also their literatures of different types of parking systems and its difference between have been observed.

The problems regarding the existing system have been found such as, Complicated programming, High budgets, Unfeasible design, high end robots, etc.

Taking problem statement from above and studying the fundamental engineering concepts various concepts regarding modern parking system are prepared and amongst those best concepts design has been selected for further phases.

Putting the ideas on the modelling software for visualisation of the prototype and making it more and more compatible so that there will be less complexity in designing

In this phase material selection is done and also its procurement as per need the dimensions are taken fromCATIA model.

This phase includes fabrication of prototype in the workshop from the procured material and preparing the Prototype model from the software model.

This phase include Assembly of all the sub parts, also the arrangement of the motor and its wiring is done, all finishing operations like grinding, trimming, painting is done here. Testing phase includes testing of the Prototype model under real environment.

Vertical Car Parking model has been designed; all the parts in it were manufactured and assembled and tested successfully.

Analysis of the model has been done and developed with the scaling of 1:9 for life size model Such as SUV’s like Fortuner.

As the life cycle model involves proper design and advanced methods are to be used to meet the requirements of the customers.

[1] S S RATTAN, Theory of Machines, 4th Edition, Mcgraw Hill Education (India) Private Limited

[2] R. K. Jain, Production Technology, 17th Edition, Khanna Publications Private Limited

[3] V B Bhandari, Design of Machine Element, Mcgraw Hill Education (India) Private Limited

[4] R. K. Rajput, Strength Of Meterials, S. Chand