Published on Feb 28, 2025

A shock absorber is a mechanical device designed to smooth out or (A slight wetness) damp a sudden shock impulse and dissipate kinetic energy. Now the project has mainly concentrated a suitable suspension unit has been designed. In a vehicle, it reduces the effect of traveling over rough ground. With shock absorbers, the vehicle would have a bouncing ride, as energy is stored in the spring and then released to the vehicle, possibly exceeding the allowed range of suspension movement.

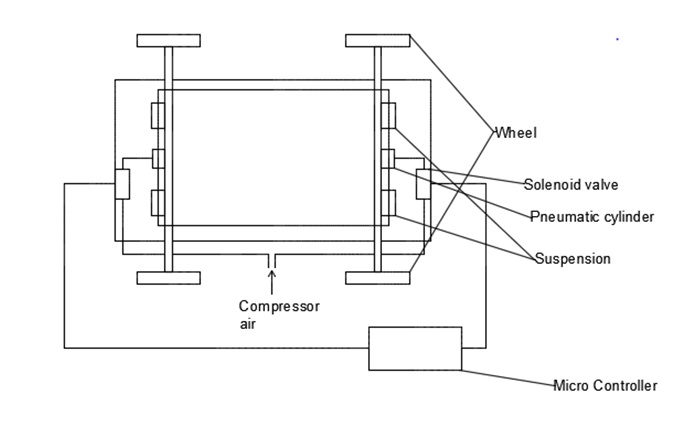

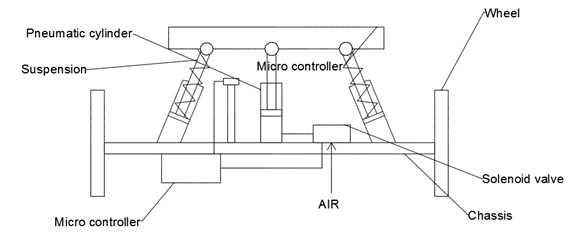

Control of excessive suspension movement with shock absorption requires stiffer (higher rate) springs, which would in turn give a harsh ride. Shock absorbers allow the use of soft (lower rate) springs while controlling the rate of suspension movement in response to bumps. This system consists of pneumatic suspensor, compressed air and solenoid valve. Shock absorbers are an important part of (2-wheeled motor vehicle; usually propelled by an internal combustion engine) automobile (A mixture in which fine particles are suspended in a fluid where they are supported by buoyancy) suspensions.

This is an era of automation where it is broadly defined as replacement of manual effort by mechanical power in all degrees of automation. The operation remains an essential part of the system although with changing demands on physical input as the degree of mechanization is increased.

Degrees of automation are of two types, viz.

• Full automation.

• Semi automation.

In semi automation a combination of manual effort and mechanical power is required whereas in full automation human participation is very negligible.

Automation can be achieved through computers, hydraulics, pneumatics, robotics, etc., of these sources, pneumatics forms an attractive medium for low cost automation. The main advantages of all pneumatic systems are economy and simplicity. Automation plays an important role in mass production.

For mass production of the product, the machining operations decide the sequence of machining. The machines designed for producing a particular product are called transfer machines. The components must be moved automatically from the bins to various machines sequentially and the final component can be placed separately for packaging. Materials can also be repeatedly transferred from the moving conveyors to the work place and vice versa.

The important components of our project are,

• Pneumatic suspension system

• Control Unit with Power supply

• Solenoid Valve

• Flow control Valve

• Air Tank (Compressor)

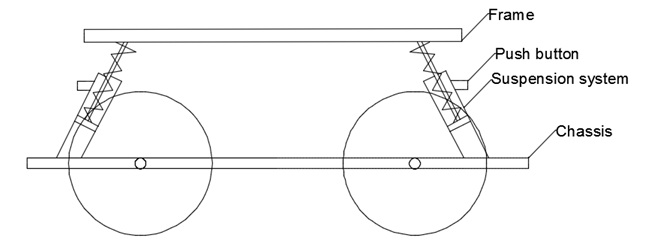

The push button switch is fixed near to the front and back wheel suspension arrangement. The switch was ON at the time of front and back wheel suspension, the control signal is given to the electronic control unit. The electronic control unit is activating the solenoid valve for the particular time period only. The solenoid valve stem is open, the compressed air flow from the air tank to the flow control valve.

The compressed air flow is controlled by the valve is called “FLOW CONTROL VALVE”. This air flow is already set. Then the compressed air goes to the back and front wheel suspension arrangement of pneumatic cylinder. The pneumatic cylinder piston moves forward at the time of compressed air inlet to the cylinder.

It requires simple maintenance cares

The moving parts of this system are cooled by the oil itself used. Thus this project does not require any cooling arrangements.

Checking and cleaning are easy, because of the main parts are screwed.

Repairing is easy.

Replacement of parts is easy.

1. Initial cost is high.

2. High maintenance cost.

It is very much useful for Car Owners & Auto-garages.

Four wheeler Application

Thus it can be useful for the following types of four wheeler vehicles;

1) MARUTI, 2) AMBASSADOR, 3) FIAT, 4) MAHINDRA, 5) TATA